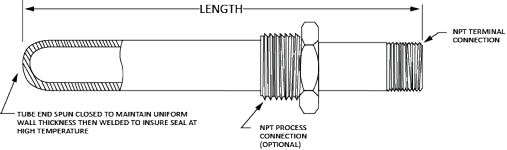

Dense, fine grained, nonporous compositions that remain gas tight even at temperatures near their melting point. Ceramic tubes are generally used at high temperatures with platinum type thermocouples although use with base metal thermocouples is prevalent in atmospheres harmful to metal tubes but not subjected to mechanical damage. Ceramic tubes will sag at temperatures below their maximum working temperatures, so if they are installed horizontally and used above their sagging temperatures they should be fully supported. Sag temperature is temperature at which the tube will sag 1/4″ in one hour. Ceramics will retain moisture at room temperature. This moisture may become trapped in the ceramic and cause the destruction of the tube when the tube is thermally shocked. It is recommended that preheating or slow heating of ceramic tubes to 400 to 800 °F be done in order to drive off this moisture before high heat is introduced.

Porous and highly refractory. They are used to temperatures of 1650°C (3000°F) as secondary protection against extreme temperature, abrasive atmospheres and direct flame impingement. Silicon Carbide tubes are moderate in cost. Primary mullite or alumina tubes are recommended with these tubes.

Silicon Carbide

A pressureless, sintered form of alpha silicon carbide with a density greater than 98% theoretical. Having a very fine grain structure and being 50% harder than tungsten carbide makes it resistant to erosion. It contains no free silicone, which makes it highly chemical resistant in both oxidizing and reducing environments. For use in air to 1650°C (3000°F). SA SiC tubes are high in cost.

Single-Phase Silicon Carbide Tubes

A high cost combination of chromium and alumina for use to temperatures of 1205°C (2200°F) that provides excellent oxidation resistance, thermal conductivity comparable to that of stainless steel, good resistance to wetting by most molten metals. A primary alumina tube is recommended when this tube is used in conjunction with platinum thermocouples.

Metal Ceramic Tubes

Offer the mechanical protection of metal tubes and the corrosion resistance of ceramics. For molten aluminum and zinc applications, they resist erosion, will not contaminate metal melts, and may outlast iron tubes by many times depending on the application.

Refractory Laminated, Metal Tubes

Offer good mechanical protection for base metal thermocouples up to 1150°C (2100°F) in oxidizing atmospheres. All metals are porous after about 870°C (1600°F) so it may be necessary to provide a ceramic primary tube to protect the thermocouple from detrimental vapors.