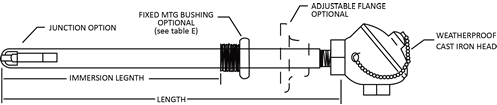

Example: K-12-600-24″

Type K Thermocouple, 1/2 NPT, Inconel 600 Tube, 24″ long

NOTE: In the Chart below, A refers to Table A (Thermocouple Type), B refers to Table B (Protecting Tube Size), C refers to Table C (Protecting Tube Material), D refers to the Assembly Length from 12″, in 6″ increments, E refers to Table E (Mounting Bushing) and F refers to the Table Notes. If you have any questions, please contact us.

| PROTECTING TUBE | PART NUMBER | |

|---|---|---|

| MATERIAL | SIZE NPT | (see Tables A,B,C,E and Notes below) |

| CARBON STEEL | 1/4 NPT | A-14-118-D-E-F |

| 1/2 NPT | A-12-118-D-E-F | |

| 3/4 NPT | A-34-118-D-E-F | |

| 1 NPT | A-44-118-D-E-F | |

| 304 SS | 1/4 NPT | A-14-304-D-E-F |

| 1/2 NPT | A-12-304-D-E-F | |

| 3/4 NPT | A-34-304-D-E-F | |

| 1 NPT | A-44-304-D-E-F | |

| 316 SS | 1/4 NPT | A-14-316-D-E-F |

| 1/2 NPT | A-12-316-D-E-F | |

| 3/4 NPT | A-34-316-D-E-F | |

| 1 NPT | A-44-316-D-E-F | |

| 446 SS | 1/4 NPT | A-14-446-D-E-F |

| 1/2 NPT | A-12-446-D-E-F | |

| 3/4 NPT | A-34-446-D-E-F | |

| 1 NPT | A-44-446-D-E-F | |

| INCONEL 600 | 1/4 NPT | A-14-600-D-E-F |

| 1/2 NPT | A-12-600-D-E-F | |

| 3/4 NPT | A-34-600-D-E-F | |

| 1 NPT | A-44-600-D-E-F | |

NOTES:

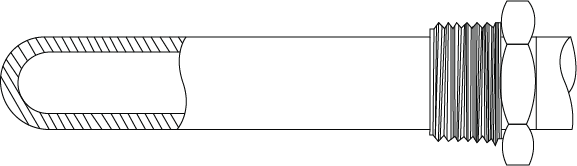

- Schedule 40 protecting tubes are standard, for extra-heavy schedule 80 use code “H” (e.g. K-12-600-24″-0-H).

- For open end, exposed T/C junction construction, use suffix “X” (e.g. 12-304-12″-0-X)

| TABLE A - THERMOCOUPLE TYPE | ||

|---|---|---|

| THERMOCOUPLE TYPE | SINGLE ELEMENT | DUAL ELEMENT |

| Chromel vs Alumel | K | K2 |

| Iron vs Constantan | J | J2 |

NOTES:

- All assemblies are plain junction unless otherwise specified.

- For insulated junction, insert “U” (e.g. KU-12-600-24″).

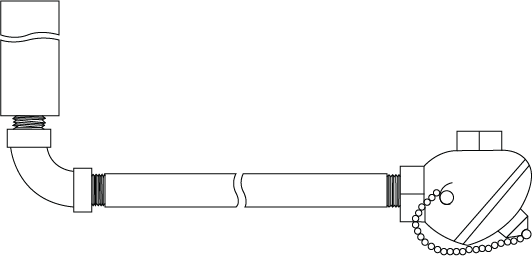

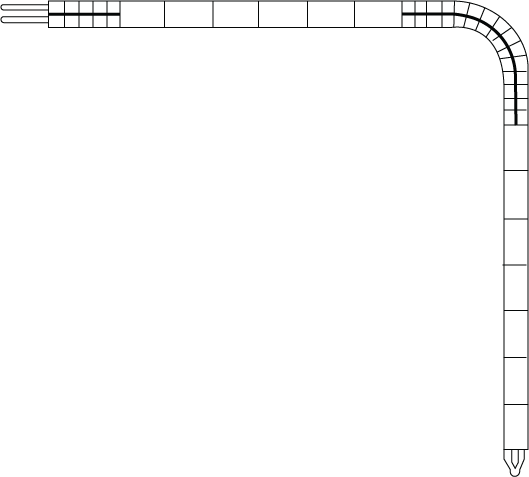

- For angle type assembly, insert “A” code (e.g. KA-12-600-24″).

For other than 18″ cold leg specify cold leg length (e.g. KA(24″)-12-600-24″).

| TABLE B - PROTECTING TUBE SIZE | ||||||

|---|---|---|---|---|---|---|

| PROTECTING TUBE SIZE | ORDER CODE | T/C ELEMENT REPLACEMENT | HEAD & BLOCK REPLACEMENT | |||

| NPT | I.D. x O.D. | SINGLE ELEMENT | DUAL ELEMENT | SINGLE ELEMENT | DUAL ELEMENT |

|

| 1/4 | 0.364 x 0.540 | 14 | 14-A-R1-D | 14-A2-R4-D | AWC-1/4 | DWC-1/4 |

| 3/8 | 0.493 x 0.675 | 38 | 14-A-V1-D | 14-A2-R4-D | AWC-3/8 | DWC-3/8 |

| 1/2 | 0.622 x 0.840 | 12 | 08-A-V0-D | 14-A-V1-D (2 pcs.) | AWC-2 | DWC-2 |

| 3/4 | 0.824 x 1.050 | 34 | 08-A-V0-D | 08-A-V0-D (2 pcs.) | AWC-3 | DWC-3 |

| 1 | 1.049 x 1.315 | 66 | 08-A-V0-D | 14-A-V1-D (2 pcs.) | AWC-4 | DWC-4 |

NOTES:

- Schedule 40 protecting tubes are standard, for extra-heavy schedule 80 use code “H” (e.g. K-12-600-24″-0-H).

- For open end, exposed T/C junction construction, use suffix “X” (e.g. 12-304-12″-0-X)1)

- Weatherproof cast iron head is standard, for WP aluminum head use suffix “WA” (e.g. K-12-600-24″-WA).

- For general purpose aluminum head, use suffix “GP” (e.g. K-12-600-24″-GP). Not available in dual element.

- 1/4 NPT & 3/8 NPT heads utilize reducer bushings.

| TABLE C - PROTECTING TUBE MATERIAL | ||||

|---|---|---|---|---|

| MATERIAL | ORDER CODE | MAX. WORKING TEMPERATURE | APPROX. MELTING TEMPERATURE | REPLACEMENT PROTECTING TUBE CODE |

| CARBON STEEL | 118 | 1300°F | 2500°F | B-118-D-E |

| 304SS | 304 | 1650°F | 2560°F | B-304-D-E |

| 316SS | 316 | 1700°F | 2500°F | B-316-D-E |

| 446SS | 446 | 2000°F | 2700°F | B-446-D-E |

| INCONEL 600 | 600 | 2100°F | 2550°F | B-600-D-E |

| TABLE E - MOUNTING BUSHING | ||

|---|---|---|

| FIXED BUSHING SIZE | PART NO. (Steel) | PART NO. (SS) |

| 1/2 NPT | F12C | F12S |

| 3/4 NPT | F34C | F34S |

| 1 NPT | F44C | F44S |

| 1-1/4 NPT | F54C | F54S |

| 1-1/2 NPT | F64C | F64S |

Notes:

1/2 NPT Bushing fits up to 3/8 pipe.

3/4 NPT Bushing fits up to 1/2 pipe.

1 NPT Bushing fits up to 3/4 pipe.

1-1/4 NPT Bushing fits up to 1 pipe.

1-1/2 NPT Bushing fits up to 1-1/4 pipe.

GIVE IMMERSION LENGTH WHEN ORDERING BUSHING (e.g. 12-304-24″-F34C-18″).