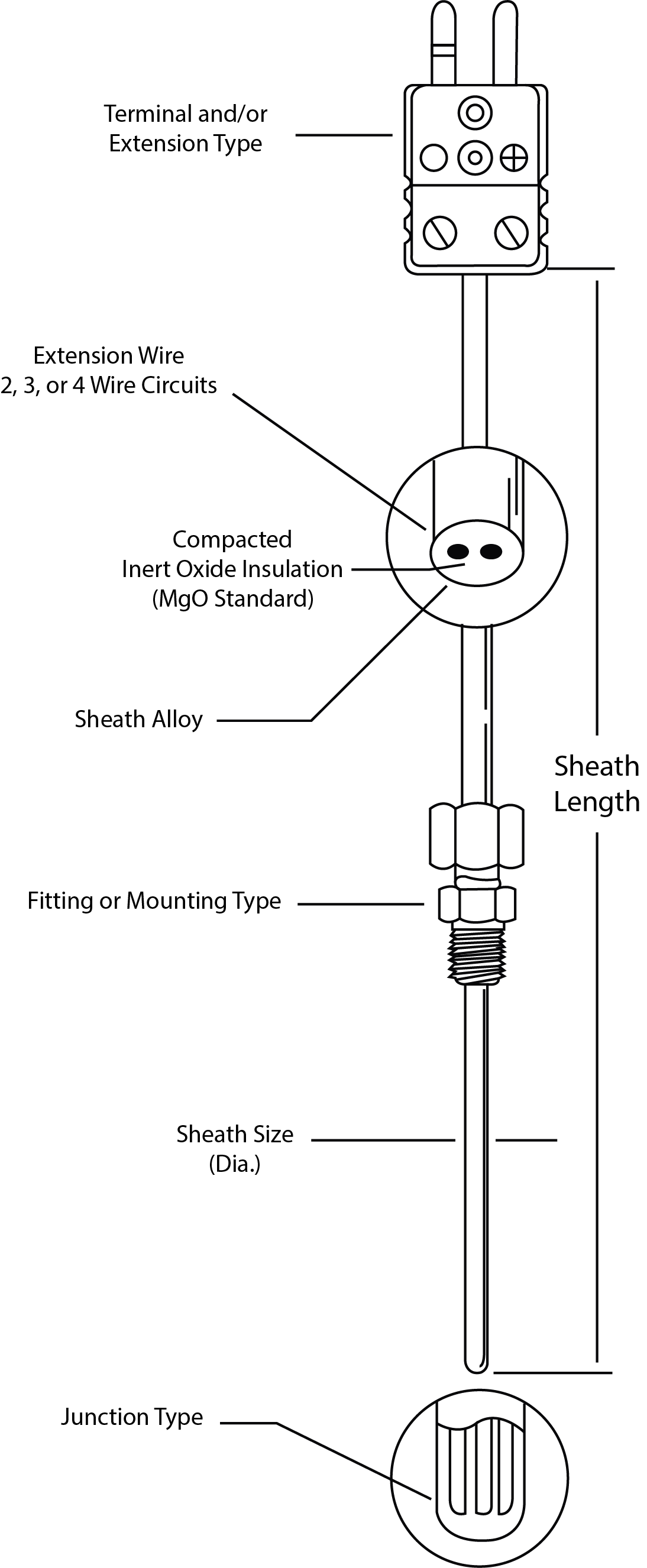

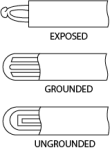

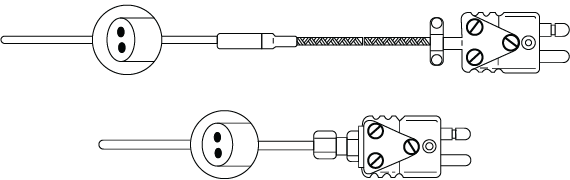

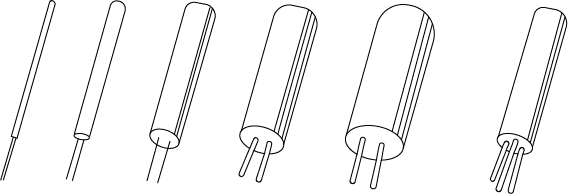

Metal Sheathed – Inert Oxide Insulated

Marlox is metal sheathed, inert oxide insulated thermocouple cable from marlin manufacturing Corporation. Available within ANSI/ASTM calibratioin tolerances and with various types of sheath alloys. Marlox can be ordered as complete fabricated assemblies or in random lengths. Drawn to final size and fully annealed standard Marlox, single or dual thermocouple element, is moisture-proof, pressure resistant, accurate, bendable and weldable. Quality control procedures insure that all thermocouple material is tested for adequate insulation resistance. All certified Marlox stock is checked for ANSI/ASTM limits of error conformance by lot sampling in our quality control metrology laboratory, which is certified traceable to the National Institute of Standards and Technology (NIST) and ISO 17025 NVLAP accredited (Lab Code 2000512-0). Post assembly certified traceable calibration is available upon request.

For more information regarding Calibration Services – Click Here!

THERMOCOUPLE DO’s:

- DO check in place.

- DO replace at established, proper intervals.

- DO have good connections throughout the circuit.

THERMOCOUPLE DO NOT’s:

- DON’T reinsert at different immersions. (Avoid decreasing the immersion).

- DON’T use for accurate measurements at lower temperatures after being exposed to higher temperatures.

- DON’T use in defective protecting tubes.

- DON’T insulate with used insulators.

- DON’T use oils and solvents on or in T/C’s or T/C assemblies.

For more information regarding General Installation, Operation and Maintenance of Thermocouples click here!