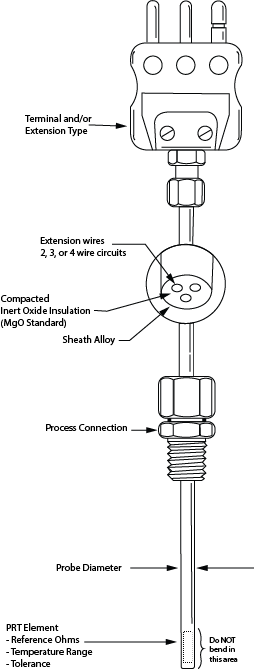

Select the PRT element that will be capable of operating in your application range. The reference resistance (100 Ohms@0°C – typical) and temperature coefficient (Alpha of 0.00385 – typical) must match the instrumentation in your system.

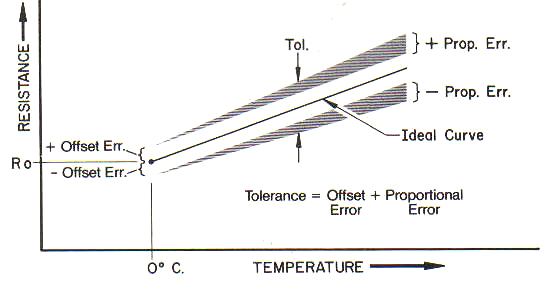

The Platinum Resistance Element of the standard Marlin PRT has a base or reference resistance of 100 Ohms @ 0°C, a temperature coefficient alpha of 0.00385, and a tolerance (limit of error) class of 0.1%. Marlin elements are of wire wound construction. Other resistances, temperature coefficients and tolerances are available to fit your requirements.(Please consult the factory.)

The Platinum Resistance Element 1

| Marlin Type | Reference Ohms | Wire Wound Element Temperature Range | Alpha |

| P1 - Single | 100 | -250°C to 600°C (-420°F to 1112°F) | 0.00385 |

| P2 - Dual | 100 x 2 | -250°C to 600°C (-420°F to 1112°F) | 0.00385 |

Wire wound elements consist of fine, high purity platinum wire wound and imbedded in an insulation. The compacted MgO insulated construction of standard Marlin PRT’s provides maximum durability and dependability for industrial PRT applications. All elements are carefully annealed and mounted so that the sensing wire remains strain free under severe, heavy-duty applications. Each element will have its own characteristics and therefore each PRT must be tested to insure it is within tolerance.

Single Element PRT’s are most commonly used but dual units are available for simultaneous recording, controlling and indicating of a single thermal point. Also, higher resistances are available but it should be noted that resistances above 100 Ohms and multiple elements require larger probe diameters (minimum 0.250″) and are more expensive.

Temperature Resistance Relationship

Over the temperature interval -200 to 600 °C, the resistance of a platinum resistance thermometer is given by the relationship:

Rt = R0 [1 + At + Bt2 + Ct3 (t – 100)]

where Rt is the resistance in ohms at any temperature t (expressed in degress Celsius), and R0 is the resistance in ohms of the thermometer at 0°C. A, B, and C are constants whose values are:

- A =3.9083 x 10-3

- B =-5.775 x 10-7

- C =-4.183 x 10-12

The C constant is used only for temperatures below 0°C. For all temperatures above 0°C, the C constant is set equal to zero, and the last term of the expression may be ignored.

Amperage – Self Heating

The amperage is limited by self-heating. Currents in excess of 10 mA through the elements are not recommended. The error caused by self-heating is typically less than 0.1°C temperature rise in water for a 5 mA current.

Inductance

Negligible for common AC use.

Insulation Resistance is greater than:

The Platinum Resistance Element 2

| 100 Megohms | @100 Volts DC and 25°C |

| 10 Megohms | @10 Volts DC and 100 to 300°C |

| 2 Megohms | @10 Volts DC and 301 to 650°C |

| 0.5 Megohm | @10 Volts DC and 651 to 850°C |

Repeatability

After 10 cycles to high temperature limits is less than the adjustmenterror for the corresponding tolerance class.

Alpha the Temperature Coefficient is defined as:

R100 – R

0 (Ohms) / 100 x R

0(Ohms °C) and is related to A & B by the expression alpha = A + 100B, where alpha = 0.00385 for P1.