Products

Sensors - Platinum Resistance Thermometers - Tolerance of the PRT Element

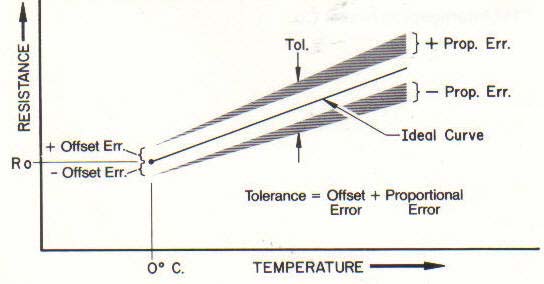

The accuracy of a platinum resistance thermometer is dependent upon two factors:

- The offset

of its actual resistance from the nominal value (typically 100

ohms) at some reference temperature

(usually 0°C). - Variation from a nominal value of the effective resistance temperature coefficient over a given temperature interval, giving rise to an additional error component that is proportional to the temperature.

Both of these

factors are variable from sensor to sensor, but their magnitude

limits are implicit for a given tolerance 'class'.

The designation of a PRT tolerance class is based on the percent allowable variation, in ohms, of the nominal resistance value at the reference temperature. However, for convenience, this ohmic tolerance is often expressed as an equivalent °C temperature variation. To this base uncertainty must be added the allowable proportional error for the class, which is stated as a percentage of measured temperature. This percentage applies when temperatures are expressed in degrees Celsius. A tolerance in degrees Fahrenheit is obtained by multiplying the Celsius equivalent sum temperature tolerance by 9/5.

Tolerance = Offset Error + Proportional Error

| Marlin Code | Tolerance Class | Offset Error | Proportional Error (°C) | *Sum of Errors (°C) |

|---|---|---|---|---|

| 0 | 0.05% | 0.15°C | 0.3% (T) | 0.15 + 0.003 (T) |

| 1 | 0.1% | 0.3°C | 0.5% (T) | 0.3 + 0.005 (T) |

| 2 | 0.5% | 1.3°C | 0.8% (T) | 1.3 + 0.008 (T) |

*(T) is the temperature in °C without regard to sign.

|

|---|

PRT CIRCUITRY

Resistance bridge techniques are used with resistance thermometers for temperature measurement. In these techniques the resistance change with temperature of the PRT, which is the basis for a resistance thermometer, can be affected by the lead resistance. marlin offers various circuits to fulfill the requirements of your instrumentation.

The accuracy of a PRT may be independent of the distances between the sensor and the instrument whether it be an indicator, recorder, controller, data logger or computer. Click Here For More Information Regarding Marlin Instruments! The distance may vary from a few inches to many miles. Copper hook-up wire is generally used between the sensor and instrument.

The comparatively high signal level of the PRT eliminates the need for high gain amplifiers and generally reduces the susceptibility of the measuring system to noise and signal interference.

| Marlin Code | Circuit Type |

|---|---|

| 12 | 2-Wire Single Element |

| 13 | 3-Wire Single Element |

| 14 | 4-Wire Single Element |

| 15 | 4-Wire

Single Element Compensating Loop |

| 22 | (2) 2-Wire Dual Element |

| 23 | (2) 3-Wire Dual Element |